Processing Machine

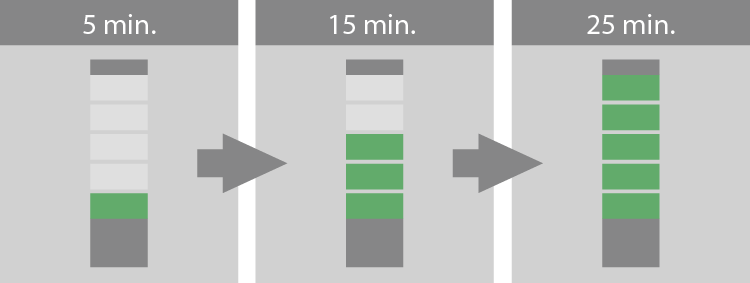

At the factory with many processing machines at work, the sign of trouble or periodic maintenance can be managed by displaying easily comprehensible color arrays to grasp the circumstance of all equipment in a diverse "luminescence color", and stablize their operation.In addition, if an abrupt increase occurs, quick action can be achived, since detailed circumstances of all equipment is already displayed and can be judged based on known information.

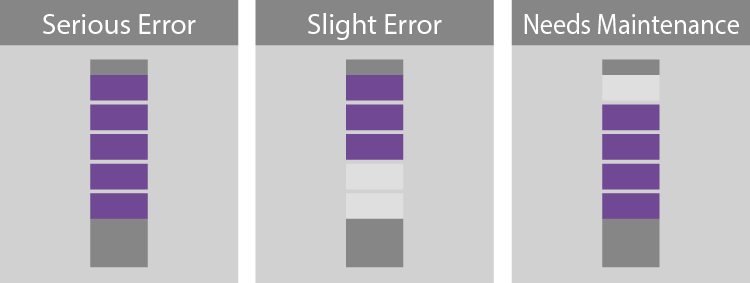

Lighting Method: "Detailed Error Display"

The level of information (serious error, slight error) can be expressed colorfully.